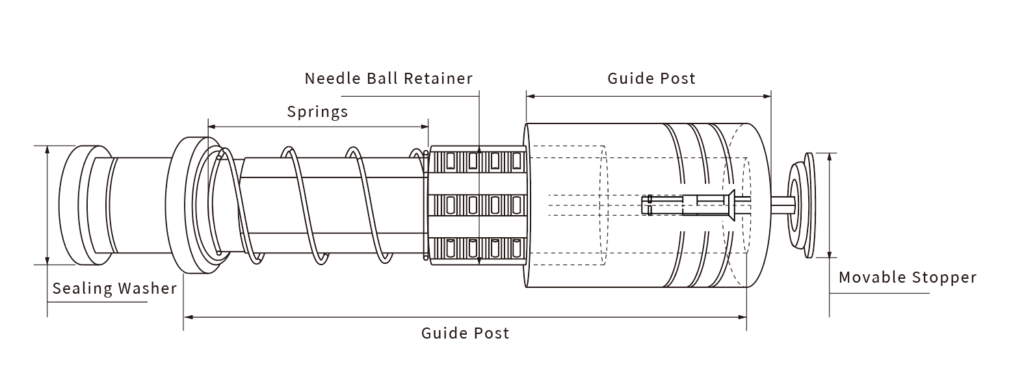

Application of hexagonal needle roller guide pillar

Hexagonal needle roller guide pillar is a mold accessory, which plays an important role in several fields. The following are its main application scenarios:

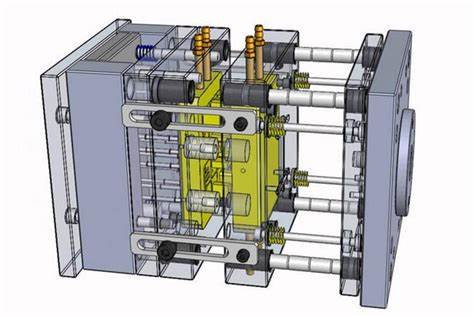

Plastic mold field: plastic mold processing requires high-precision, high-stability mold accessories, and hexagonal needle roller guide pillar is one of the key accessories to meet this demand. In the plastic mold, the hexagonal needle roller guide pillar reduces the friction of the mold and improves the service life and production efficiency of the mold through the action of the guide.

Stamping dies: Stamping dies are usually used to manufacture various plates, strips and metal parts of various shapes. Hexagonal needle roller guide pillars are often used for clamping and positioning in mold accessories, so as to ensure the machining accuracy and machining quality of the workpiece.

Die-casting mold field: Die-casting molds are often used to make various high-precision metal parts, such as auto parts, electronic parts, etc. Hexagonal needle roller guide pillars also play an important role in die casting molds, ensuring the normal operation of the mold and the precise manufacturing of parts.

In addition to the above main application scenarios, there are some additional application scenarios as follows:

Precision machinery: In precision machinery, hexagonal needle roller guide pillars are often used to ensure the precise movement and positioning of mechanical components. Due to its high accuracy and stability, hexagonal needle roller guide pillars help to improve the overall performance and reliability of machinery.

Automation equipment: In automated production lines and robotics, hexagonal needle roller guide pillars are used to support and guide moving parts to ensure the precise and efficient operation of the equipment.

Aerospace: In the aerospace sector, the precision and reliability of components are extremely demanding. Hexagonal needle roller guide posts can be used for the manufacture and assembly of critical components to ensure the safety and performance of aircraft.

Automobile manufacturing: In the automobile manufacturing process, hexagonal needle roller guide pillars can be used in various molds and fixtures to improve the accuracy and consistency of parts, thereby ensuring the quality and performance of automobiles.

It should be noted that different application scenarios may have different requirements for the material, size and accuracy of the hexagonal needle roller guide pillar. Therefore, when selecting and applying hexagonal needle roller guides, they need to be customized and optimized according to specific needs and scenarios. At the same time, it is recommended to cooperate with a professional mold parts supplier or manufacturer to ensure that the right hexagonal needle roller guide pillar is selected and the best application results are obtained.