Do You Know How to Install Cross Type Roller Guides

Crossed roller guide rails are widely used in life and can be applied to it in many fields. Especially in the machine equipment, the cross guide rail plays a very important role, but with the increase of the use of cross guide rail, wear and tear more and more serious, not timely replacement of accessories directly affect the quality.

However, it is difficult to replace the XX equipment without professional personnel or the replacement cannot meet the precision requirements. Many new customers will ask us how to replace the XX equipment. Today, I will explain how to replace the cross guide rail.

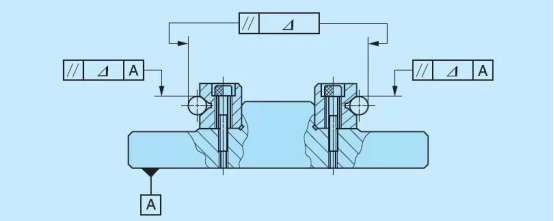

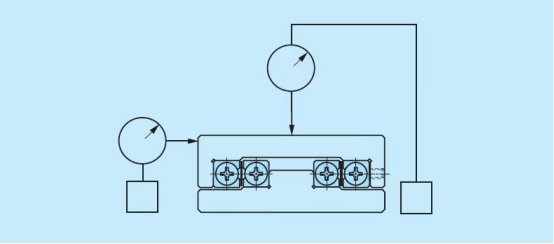

Figure 1 shows the general installation structure of the standard VR/VRAW series.

Figure 1 shows the general installation structure of the standard VR/VRAW series.

Figure 1. Installation example of VR/VRAW series standard model

Under this structure, generally install as follows.

1 Installation preparation

- Product by set (4 rails, 2 sets of cylindrical rollers with retainers) Packing. Do not mix with other sets.

- After each part is cleaned with clean detergent, apply antirust oil or lubricating oil. (Generally, the newly opened guide rail is cleaned and coated with anti-rust oil.) Remove the end screws if cleaning is desired.

2 Cleaning of mounting surface

- Remove burrs and indentations on the installation surface of the machine with oilstones. Clean the corner-clearing grooves on the installation surface.

- Wipe the foreign matter and stains with a clean cloth and apply a thin antirust oil or lubricant.

Figure 2 Mounting surface

Three 3 Base Side Rail Installation

- Align the rails correctly with the mounting surface and pre-tighten the set screws with equal tightening torque.

- Hold the rails tightly against side b (see Figure 3) while tightening them evenly using the specified torque.

- When high walking accuracy is required, confirm the parallelism of the full length track surface of the slide rail and tighten it with specified torque.

Figure 3. Installation accuracy of slide rails

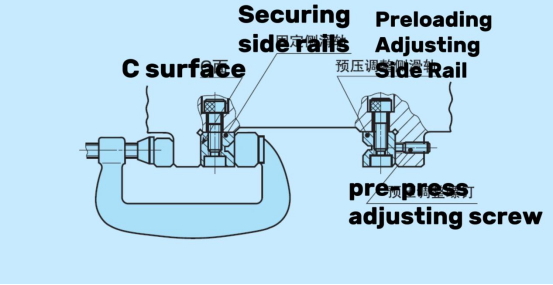

4Slide table side rail installation

- Align the fixed side rail correctly with the mounting surface and pre-tighten the set screw with equal tightening torque.

- Press the fixed side rail tightly to Face C and tighten evenly using the specified torque.

- Remove the pre-press adjustment screw, press the pre-press adjustment side rail against the mounting surface, and then slightly pre-tighten the fixing screw with equal torque.

Fig. 4 Installation accuracy of slide side rails

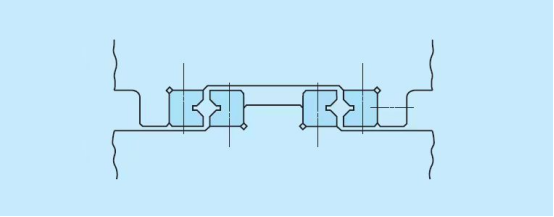

5Assembly of Sliding Table and Base

- In order to insert a cylindrical roller with a retainer between a slide table side slide rail and a base side slide rail,The position of height and width must be adjusted.

- Carefully insert the cylindrical roller with the retainer assembly and place approximately 1 ⁄ 2 of the length of the rail center. At this time, care is taken to avoid deforming the retainer.

- Install the end screws or the end face stop plate of each slide.

● Push the whole slide table to the side of the pre-pressing adjustment screw, and then screw in the pre-pressing adjustment screw to pre-adjust the gap of the slide rail to close to zero.

Figure 5 Alignment before assembly

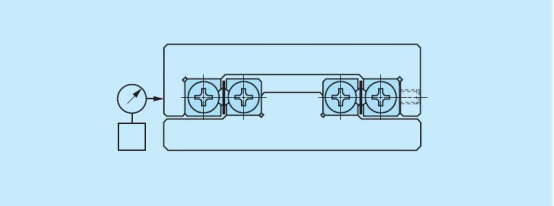

6 Pre-pressure adjustment

- The pre-pressure adjustment is performed by pre-tightening the fixing screw of the pre-pressure adjustment side slide rail.

- The pre-press adjustment starts from the pre-press adjusting screw at the center of the length of the slide rail and is alternately adjusted to both ends.

- While measuring the gap with a dial indicator on the side of the slide table, tighten the pre-load adjusting screw in sequence until the runout of the dial indicator stops. At this point, first note the tightening torque of the preload adjusting screw.

- When adjusting the pre-pressing adjusting screw close to both ends, slide the slide table quietly and ensure that there is a cylindrical roller at the corresponding position of the pre-pressing adjusting screw.

- After the above operations are completed, the preloading is not uniformly adjusted, although the preloading is in zero clearance or light preloading state. Repeat the same procedure again and adjust all the preload adjusting screws equally according to the pre-measured torque.

Figure 6 Example of Preload Adjustment Method

7 Formal tightening of the prepressing adjustment side rail

- At this time, the fixing screw is in a state that has been slightly screwed in with equal torque. Pre-tighten the set screw alternately from the middle to the ends, as when pre-pressing the adjusting screw, close to the specified torque.

- When tightening the fixing screws close to both ends, make the slide table slide quietly and make sure that there are cylindrical rollers at the corresponding positions of the fixing screws.

- At last, tighten all the fixing screws equally with the specified torque in the same method.

8 Confirmation after assembly

- Make the sliding table slide silently throughout the travel to ensure smooth running without abnormal noise.

- Measure the top and side of the slide table with a dial indicator to confirm the walking accuracy.

Fig. 7 Confirm the accuracy after assembly

The above is the installation method of VR/VRAW standard series cross roller linear guide rails.